Thin Is In – MEMS Force Sensors for Next-Gen Trackpad Design

March 7, 2024

In the past two blog posts (here and here) in this series on MEMS force sensors, I’ve been sharing how these tiny, silicon-based devices are so sensitive they can be placed under nearly any material up to two inches thick. And they are ideal for the smallest form factors, like earbuds, where size, low power, and reliability are critical to the designs.

Laptop trackpads are another ideal application for MEMS force sensors. These sensors allow trackpads to be built much thinner than today’s solutions while still delivering the same multi-function gestures we have today.

What’s In a Trackpad?

Although the trackpad looks integral to the laptop cover, it’s actually another device mounted under it. Today there are only a few major suppliers who furnish trackpads for all major laptop retailers.

Most of today’s trackpads are made up of a positioning sensing function (the pad) and a mechanical actuator for the click function. Capacitive sensing provides the position, as is done with current touch screens. Using capacitive sensing enables all the different gestures we can use to control the laptop—single finger to position the cursor, two fingers to swipe and move objects like maps, and three or more fingers for swiping to other workspaces or screens.

The click function is done with a mechanical actuator, which is an arm that extends across the trackpad surface and closes a circuit when pressed. You can notice how this arm affects the click function. At the bottom of the trackpad, the click movement is shorter—and thus takes less force—than at the top of the trackpad.

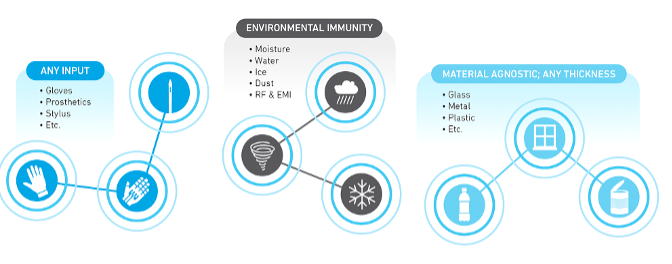

Transforming Touch with Qorvo SensorFusion™

Qorvo's sensors transform touch and elevate your end user's experience. Our technology works with a multitude of inputs, is immune to most environmental factors and works with any material.

The arm and actuator combination turns out to require the trackpad to be relatively thick, which presents a challenge to laptop designers and manufacturers, who continually try to make the PC thinner and thinner with each new generation of products. While thin is in for laptops, one of the limiting factors is the thickness of the trackpad due to the actuator arm.

MEMS Force Sensors Enable Super Functional, Thin Trackpads

MEMS force sensors are extremely small, measuring about a millimeter on each side. They are mounted on a PCB, just like any other surface-mounted electronic device, making manufacturing a well-known process. Since they can sense surface deflection as little as a few nanometers, the surface travel of the trackpad can be very short.

Today’s trackpad surfaces must be flexible enough to move the mechanical actuating arm when pressed. With MEMS force sensors, the material can be stiffer and thus thinner. That gives designers incredible flexibility to build trackpads out of just about any material—from glass and aluminum to titanium to durable clear plastic. Plus, thinness gives manufacturers and product designers more flexibility to make the laptop thinner, add features, add battery size, or all the above.

PC manufacturers are always looking for ways to differentiate their products. Often it can come down to aesthetics. MEMS force sensors give trackpad designers new options for creating unique looks for their products, setting them apart from their competitors and giving PC manufacturers a differentiating feature.

A very unique possibility is the ability to create a richer functioning laptop top plate. Instead of a knockout for the trackpad, the entire top skin below the keyboard can be a single surface, with the trackpad essentially hidden from view.

MEMS force sensors also allow designers to add more functionality to the top of their laptop design simply by placing sensors where they want to add a new button, without the need for a physical knock out and added mechanical manufacturing. When it comes to trackpads and laptop covers, MEMS force sensors enable new design experimentation and exploration.

MEMS force sensors can detect different levels of pressure on them. This analog force sensing allows the user to custom-tune the force required to register a press, whether it’s a single- or multi-level press. A multi-level press can map different functions. So, instead of a left and right button, as with today’s trackpads, there could be multi-level functions enabled by the amount of force applied to the trackpad. A light press can activate a function, a harder press might select a parameter, and the hardest pressure might change that parameter. Innovative application functions can be built from a single sensor.

Working with MEMS Force Sensors

Qorvo’s MEMS force sensors give trackpad engineers a creative design freedom they have not had. Functionality can be applied under any surface, using any material, without requiring the mechanical components used today, resulting in thinner and simpler designs. And these sensors give designers new flexibility and freedom to explore new and unique ideas for trackpads and laptop top covers.

MEMS force sensors are ideal for next-generation designs. Careful integration depends on several factors. Placement, sensitivity, overlaying materials, software, and other technologies that might be used are all critical to the successful integration of a sensor in a design. Thus, when considering your design with a MEMS force sensor, it’s important to consult with the manufacturer to help ensure the success of the design. The manufacturer can provide insight into a design and help engineers select and integrate devices to achieve the success they seek.

Qorvo offers extremely sensitive MEMS force sensors. These sensors are very small, predictable and low power, enabling low-cost, reliable trackpad designs. Qorvo also can offer end-to-end design expertise and assistance, simulation capabilities, and software integration to help engineers deliver product innovations. Learn more about force sensors and how Qorvo can help you integrate them into your next project.

Have another topic that you would like Qorvo experts to cover? Email your suggestions to the Qorvo Blog team and it could be featured in an upcoming post. Please include your contact information in the body of the email.